Many years ago, I started dating a new guy who was a Civil Engineering major. It was then that I realized that we could never discuss what he did all day because on one of our first dates he started talking about CAD/CAM. For all I knew he was discussing a special kind of Ewok, which I still don’t know what that is, I just assume that it’s from Star Wars and leave it at that. Anyways, my new boyfriend was actually not talking about some kind of extraterrestrial creature, but a type of software. Ah, software I could handle, especially once I realized what it could also be used for.

CAD, which I learned stands for Computer Assisted Design, and CAM Computer Assisted Manufacturing has many uses in technical fields like Engineering, but to my delight, I found out that it could also be used to design jewelry and that was something that I could definitely get on board with!

So what does CAD/ CAM do for you? Well it does a lot of things. Have you ever tried to draw a detailed picture of a pony only to have it come out looking like a cross between a duck and a hippo? Talented Artists, please don’t answer that because I certainly have. Now imagine that you were using your limited artistic skills to show a jewelry designer what you wanted your ring to look like, and it came out looking like a hippo. That would not be so good. What CAD allows us to do is use computer technology for the process of the design. We can take any drawing, even some as awful as mine, and make sense of it. CAD brings your ideas to life with incredible detail and precision, allowing you to see what your piece will look like from all possible angles, without ever leaving the comfort of your armchair.

So what does CAD/ CAM do for you? Well it does a lot of things. Have you ever tried to draw a detailed picture of a pony only to have it come out looking like a cross between a duck and a hippo? Talented Artists, please don’t answer that because I certainly have. Now imagine that you were using your limited artistic skills to show a jewelry designer what you wanted your ring to look like, and it came out looking like a hippo. That would not be so good. What CAD allows us to do is use computer technology for the process of the design. We can take any drawing, even some as awful as mine, and make sense of it. CAD brings your ideas to life with incredible detail and precision, allowing you to see what your piece will look like from all possible angles, without ever leaving the comfort of your armchair.

The photo above is a great example of how CAD technology can bring a ring to life. Every detail is measured and mapped out. It can alert the designer to any proportion, or structural issues before they become a problem. For example, height can be a problem in rings with large stones, but the CAD software lets us know that at 6.88mm, height won’t be a problem with this ring. There is one quirk inherent to CAD design though. Bulk. Prongs, and any metal work will appear larger in a CAD image then they will in real life. This is to allow for metal to be removed or shaped during polishing and setting process. Computers just haven’t been able to capture the refined qualities that finished jewelry has. Also it is important to remember that the prong that is several inches in height on the computer screen will only be a couple of millimeters tall on the actual piece.

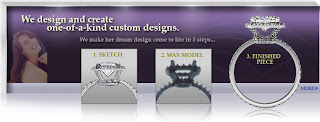

Once your piece is rendered into CAD and the design has been approved, a wax model can be created. This is a life size version of your design that you can try on, place your center stone in, and use to get a general feel for what the ring will look like on your finger. The fun thing about waxes is, the come in such bright, happy colors like hot pink, blue and yellow! The photo below is a wax that was created to hold a large central princess cut stone. All of the bumps along the band are going to be the prongs for the round brilliant diamonds that will be set in the finished ring. We were able to place the customer’s stone in the wax to give an idea of what the finished piece would look like.

So now that I’ve whet your custom design appetite. Take a minute to peruse our custom design gallery to get ideas for your next piece. Then, when everyone oohs and ahhs over it and asks, ‘Who’s it by?’ you can casually tell them that it’s an original couture design by you!

Oh, and in case any of you are Star Wars fans and were horrified that I didn’t know what an Ewok was, don’t worry. I looked it up. He’s actually quite a cute little bugger.

I hate to say it, but AutoCAD is your best bet. I took an AutoCAD class last semester, and honestly, it's not that hard.

ReplyDeleteSolidworks Support